What is an asbestos gasket?

Asbestos gaskets are made of asbestos, rubber, and heat-resistant filling materials by rolling. They are mainly used as sealing materials for pipeline flanges, high-pressure vessel flanges, internal combustion engines and various contact surfaces.

What are the classifications and uses of asbestos gaskets?

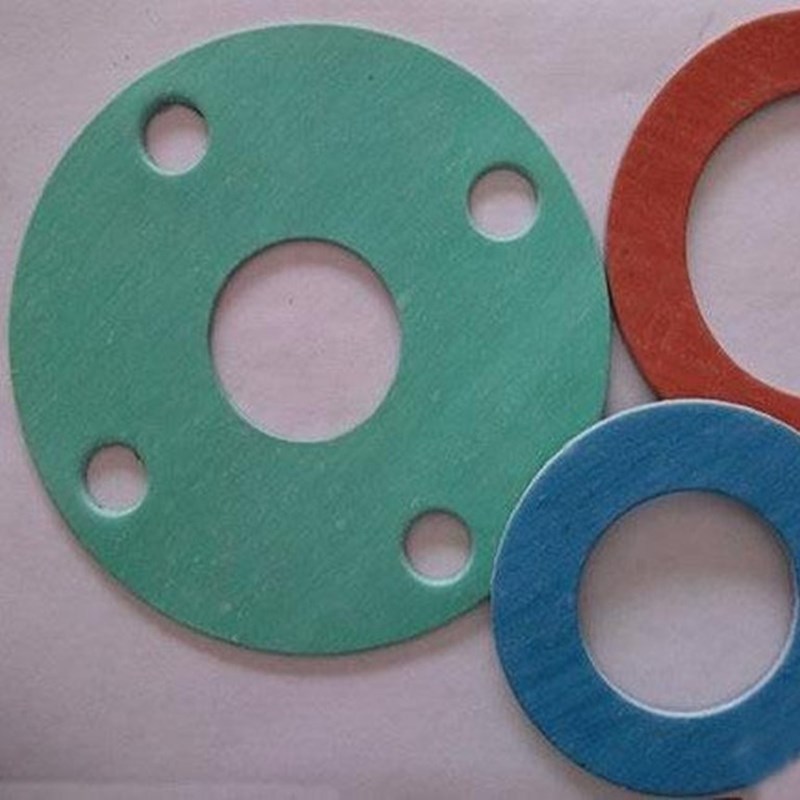

According to the asbestos content, it is divided into asbestos rubber gasket, non-asbestos rubber gasket

According to the performance of the plate, it is divided into the low-pressure gasket, medium pressure gasket, high-pressure gasket

According to the purpose of the sheet, it is divided into ordinary asbestos rubber gasket, wire mesh reinforced asbestos rubber gasket, oil-resistant asbestos rubber gasket, and acid-resistant asbestos rubber gasket.

Ordinary gasket plates are suitable for sealing of general plumbing equipment, low, medium and high-pressure water pipes and steam pipes.

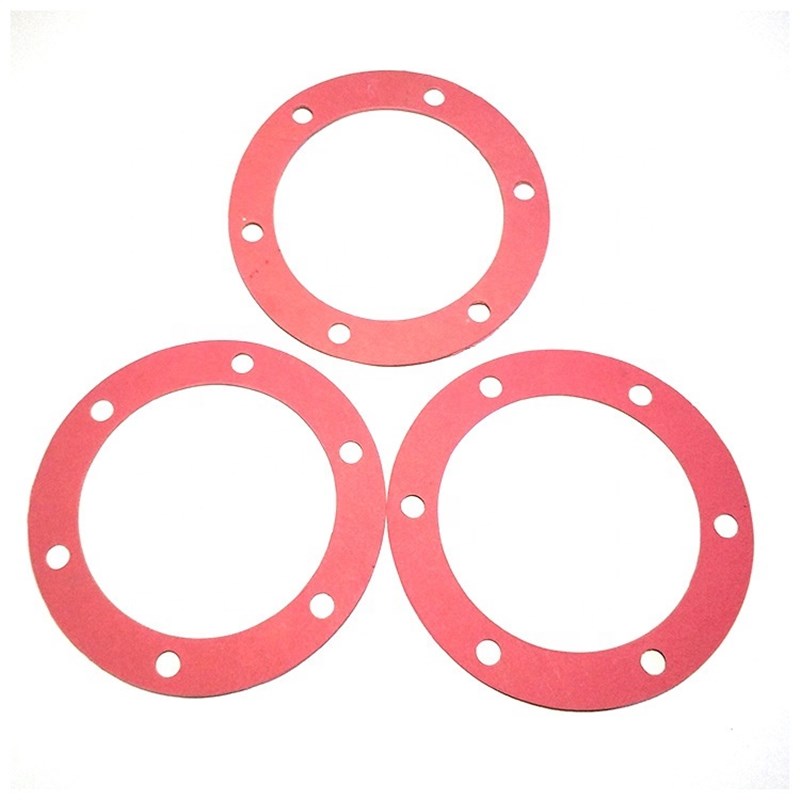

Reinforced asbestos rubber gaskets are suitable for sealing water, steam and other media.

An oil-resistant asbestos rubber sheet is suitable for the flange joints of oil refining equipment and distillation pipelines, and the sealing gaskets at the joints of automobile diesel engines and oil pipelines.

Acid-resistant asbestos rubber gaskets are suitable for sealing gaskets in acid media.

Asbestos Gasket

For sealing water, steam, inert gas, weak acid and alkali and general chemical.

Sealing fuel, oil-based lubricant, such as motorcycle engine, general machinery engine and automobile engine and petrochemical

products.

The main differences between asbestos free gaskets and asbestos gaskets lie in their material composition, temperature resistance, environmental friendliness, and applicable scenarios. Material composition: The main components of asbestos gaskets are asbestos fibers, fillers, and rubber, while non asbestos gaskets use materials such as aramid fibers, high-temperature resistant synthetic mineral fibers, and oil resistant rubber. Temperature resistance: Due to the asbestos fibers in its composition, asbestos gaskets have high temperature resistance, reaching up to 600 degrees Celsius, while asbestos free gaskets have relatively weaker temperature resistance, generally around 350 degrees Celsius. Environmental friendliness: Asbestos gaskets, due to the presence of asbestos fibers, may pose a threat to human health and have been banned from use in European and American countries. Non asbestos gaskets, on the other hand, do not contain harmful substances and are more environmentally friendly. Applicable scenarios: Asbestos gaskets are suitable for sealing water, steam, oil, solvents, medium acids, and alkalis, and are used in sealing medium and low pressure flange connections. Non asbestos gaskets are suitable for industrial pipe fittings, pumps, valves, flanges, instruments, etc. that require high hygiene standards. In summary, there are significant differences between asbestos free gaskets and asbestos gaskets in terms of material composition, temperature resistance, environmental friendliness, and applicable scenarios. When selecting, the choice of gasket should be based on specific working conditions.